14Nov

3D Printing for Design and Manufacturing Optimisation

In order to maintain our position as leaders in the aluminium industry, alimex is continually investing in cutting edge technologies and facilities.

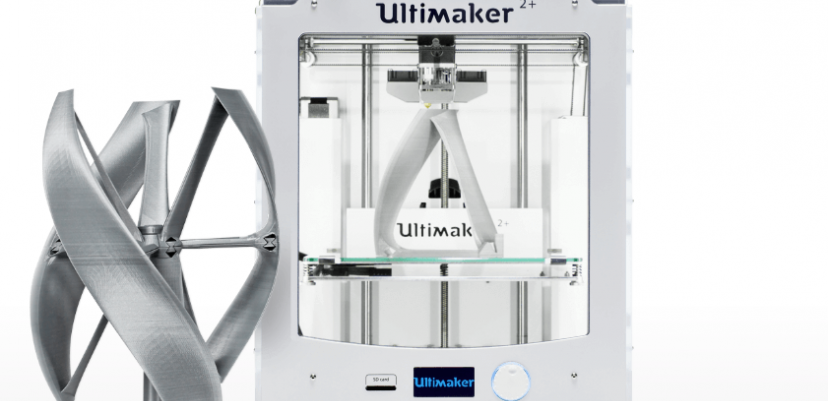

An example of this is a recent investment in our own 3D printing equipment, as a result of having this in-house we are now able to provide our clients with a fast, efficient turn-around on prototype 3D printing.

This was driven by a client who approached alimex for support with the development of a new aluminium vacuum chamber. Specifically they were in need of guidance in order to ensure production costs were viable.

There were a number of manufacturing challenges to overcome and the use of a 3D printed model ensured design teams, technical teams and manufacturing teams could all have valuable input during the design phase.

3D printing -- also known as additive manufacturing -- turns digital 3D models into solid objects by building them up in layers. The technology was first invented in the 1980s, and since that time has been used for rapid prototyping (RP). However, in recent years, 3D printing has started to evolve into a next-generation manufacturing technology.

Today it is possible to use a wide range of materials with 3D printers, including;

- Thermoplastic composites

- Pure metals

- Metal alloys

- Ceramics

- Various forms of food

However, 3D printing as an manufacturing technology is still in its infancy, but in the future in combination with synthetic biology and nanotechnology, it has the potential to radically transform many design, production and logistics processes.

alimex can support prototype build volumes of 230 x 225 x 205mm. We continually look for innovative ways to support our clients with their aluminium requirements.

Our Process

CAD Data - 3D Printed Prototype - Design & Manufacturing Optimisation - Precision CNC Machining